Dongguan delan Electronic Technology Co., LTD Telephone: 0769-81180661 Phone: 15907419126 E-mail: ian.yu@datalux.cn Address: Room 301, No. 422, Huangjiang Huancheng Road, Huangjiang Town, Dongguan city, Guangdong Province

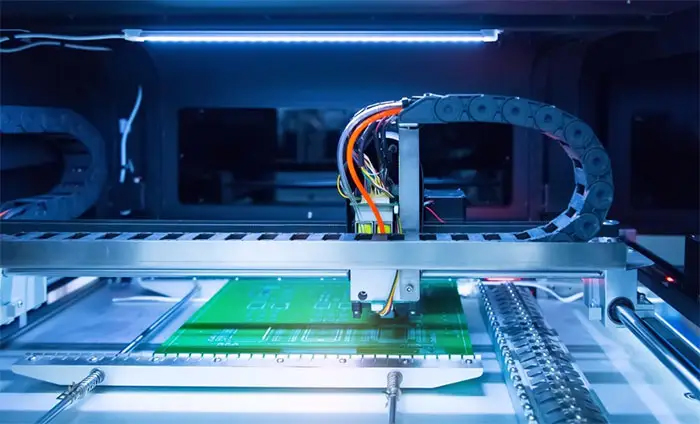

PCBA three anti-paint on PCBA waterproof, moisture-proof, dust-proof three functions, so called "PCBA three anti-paint".

Three anti paint is a special coating widely used in high-tech fields, such as automobile, home appliances, military electronics, aerospace, medical electronics and so on high-end circuit boards, can make PCBA circuit board to improve product quality, effectively greatly reduce repair. In addition, the rise of emerging industries, electric vehicle charging piles, the widespread use of unmanned aircraft, further expand the scope of use of three anti-paint.

Moisture is a common and destructive factor for PCBA boards. Excessive moisture can greatly reduce the insulation resistance between conductors, accelerate high-speed decomposition, reduce the Q value, and corrode the conductor. We often see the PCBA circuit board metal part of the patina is not coated with three anti-paint metal copper and water vapor, oxygen caused by the chemical reaction. A few hundred contaminants found randomly on a printed circuit board can be just as damaging. They can cause the same effects as moisture erosion - electronic decay, corrosion of conductors and even an irreversible short circuit.

Contaminants commonly found in electrical systems may be chemicals left over from the manufacturing process. These contaminants, for example, help fluxes, solvent release agents, metal particles and marker inks. There are also major contamination groups caused by inadvertent human handling, such as human grease, fingerprints, cosmetics and food residues. There are also many pollutants in the operating environment, such as salt spray, sand, fuel, acid, and other corrosive vapors and mold.

Tri-proof paint can be applied to printed circuit boards and components to reduce or eliminate deterioration of electronic operating performance when it may be affected by adverse operating conditions. If the coating can be maintained for a satisfactory period of time, e.g., beyond the life of the product, it is considered to have served its purpose. Even though the coating is very thin, it can withstand mechanical vibration and oscillation, thermal shock, and operation at high temperature to some extent. Of course, the notion that thin films can be used to give mechanical strength or sufficient insulation to individual parts plugged into a printed circuit board is wrong. The components must be mechanically fastened and have their own suitable caulking agent to provide double insurance against accidents.

Contact us

159-0741-9126

The company address

Room 301, No.422, Huangjiang Huancheng Road,

Huangjiang Town, Dongguan city,

Guangdong Province